ARMI vs Paving Fabrics

Paving fabrics are a common option however they introduce third party contractors that compromise QC. Long term performance is questionable. Having a RCRI that is producer made with local materials including Aramid and paver laid makes for highly improved results. One inch flexible reinforced asphalt to manage bottom up reflective cracking is optimal. ARMI can also lay over concrete.

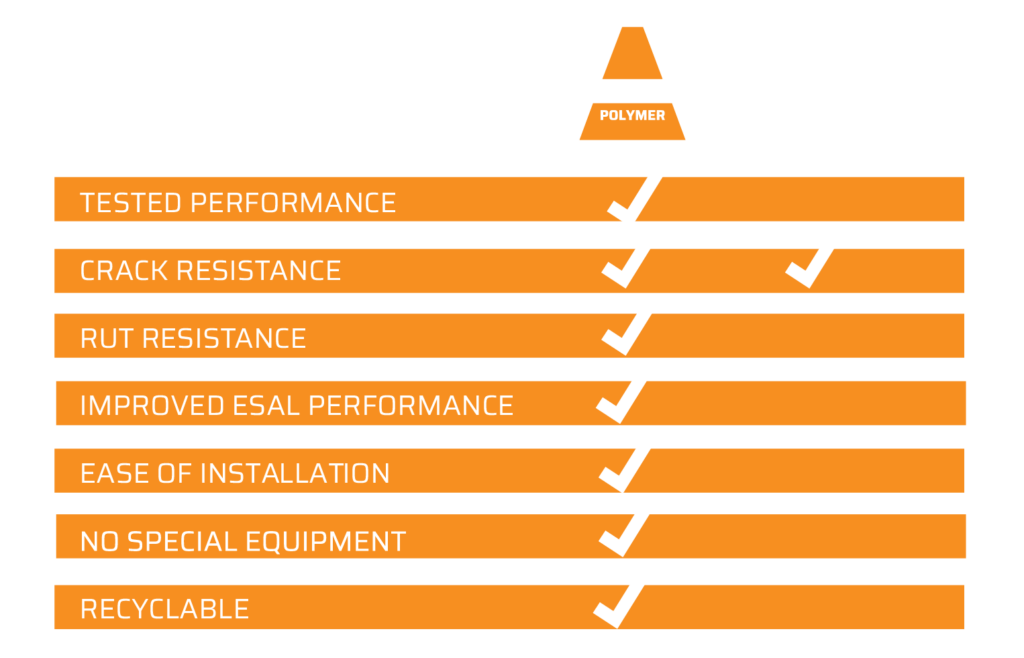

PERFORMANCE

- ARMI™ – 1” thick asphalt Flexible Reflective Crack Relief Interlayer (RCRI)

- Reduces cracking resistance by 7X

- Extends life up to 50%

EASE OF ADOPTION

- ARMI™ Plant made and paver laid

- ARMI™ formulation uses locally sourced materials

- Safe, easy and clean plant and site installation

- Precision dosing with daily reports

SUSTAINABILITY

- Longer life expectation

- ARMI™ allows for full pavement recyclablility

- No third-party site intervention

- EPD certification – Ultra low carbon additive

- Can be used to meet low carbon asphalt specs on IIJA and IRA funded projects

- Great option for future BMD compliance

- Listed in Emerald Eco Label (NAPA’s verified EPD tool)

- Helps to meet corporate ESG reporting requirements

COST SAVINGS

- Delivers cost savings versus FDR / Remove & Replace

- Longer life – reduced maintenance costs

- More cost effective than third party contractors and competing interlayers