By now every asphalt producer should have heard about the coming changes to procurement rules requiring producers to submit an Environmental Product Declaration (EPD) on federal government or federally funded projects. The problem is the information coming from the Federal government is opaque and hard to follow. This blog post is written with the producer in mind about what is driving this movement, where is all this heading, and how should the producer think about EPDs.

Why EPDs?

As discussed in the previous blog post, President Biden’s Executive Order 14507 initiated the Federal government’s regulation of embodied carbon of construction materials in direct procurement and federally funded infrastructure projects. The question then is, how does the Federal government plan to consider and mitigate the impacts of greenhouse gas emissions related to the use of construction materials? The answer is through EPDs.

EPDs is the acceptable standard for quantifying and publishing the greenhouse gas (GHG) footprint of construction materials. Almost all entities rely on EPDs to provide the data on the environmental impacts associated with the manufacturer or production of construction materials such as asphalt and concrete.

In fact, last September the Biden Administration announced it will expand the reliability, transparency, and verification of EPDs including GHG emissions reporting for actual supply chain production of asphalt and concrete materials. The Congress supported this effort when it included $100 million for program costs and $250 million for grants and technical assistance by the Environmental Protection Agency (EPA) provided in the Inflation Reduction Act (IRA) enacted last year.

How soon will EPDs be required?

The answer to that question depends on the agency. At the Federal level, the General Services Administration (GSA) as of September, 2022 requires contractors to submit an EPD as part of their “environmentally preferred asphalt standard for all GSA projects.” IRA authorized and appropriated $2.15 billion for GSA to spend on such projects.

IRA also authorized and appropriated $2 billion to the Federal Highway Administration to incentivize and prioritize low carbon asphalt mixes. These are incentive payments that will be applied to many, many highway projects across the country. The EPA under IRA is charged with determining what is an acceptable low carbon asphalt pavement mix. EPDs will be the data source for quantifying, certifying, and targeting downward the embodied greenhouse gas emissions of federally funded infrastructure projects.

State transportation agencies are already getting into the act too. State legislation has already been enacted in California, Colorado, and Oregon where state DOT’s are starting to collect EPDs from asphalt contractors. Legislation is introduced in Illinois and Minnesota to require the same.

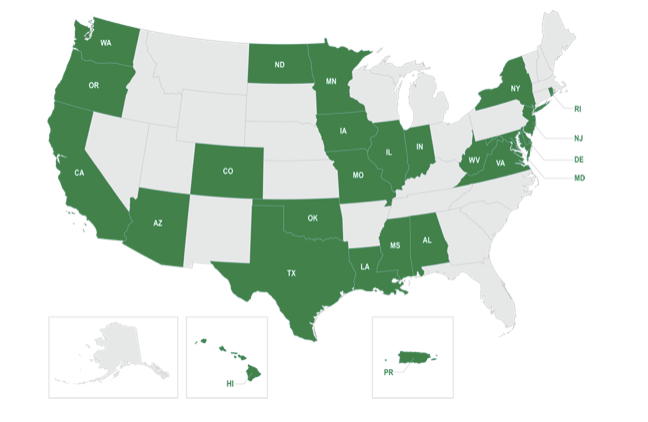

FHWA is focused on encouraging more states to adopt EPD’s to support their decision-making throughout the project delivery process. Over $7 million was awarded to 25 state departments of transportation to implement projects that quantify the environmental impacts of pavements using life cycle assessment (LCA) and environmental product declarations (EPDs). Those states in green are certainly looking at EPDs as the next step in quantifying GHG emissions.

In addition, FHWA’s Every Day Counts Program highlights the use of EPD’s at the state level and calls it a “robust environmental reporting tool,” that state transportation agencies are beginning to require and use.

How should asphalt producers think about EPDs?

First, they will be required. I expect all asphalt pavement material suppliers working on state DOT projects funded with federal dollars will need an EPD to verify their carbon footprint. In fact, as I already indicated, GSA is the first, but certainly not the last Federal agency to require EPDs. Demand for EPDs will not wane, but in fact grow exponentially as state transportation agencies work on specific strategies to reduce their carbon footprint in order to tap into the new $6.4 billion Carbon Reduction Program established in the Infrastructure Investment and Jobs Act (IIJA).

Some asphalt companies are already working on their EPD strategy, but we have a long way to go. According to EPA, only about 100 asphalt plants out of approximately 3,700 asphalt plants have a published EPD. The fact is asphalt companies that have a verifiable EPD will have a competitive advantage in the publicly funded highway marketplace. Federal and state specifiers will be able to select asphalt materials with the better environmental footprint and asphalt companies will compete based on their EPD profile.

One strategy to consider for example is for asphalt companies to buy raw materials that come with their own EPD, such as Surface Tech’s ACE XPtm. By providing more accurate results on carbon emissions using EPDs from raw material suppliers, asphalt companies will certainly look better on carbon emission reduction than any national average put out by EPA. This is yet another reason each asphalt plant needs to collect its own EPDs to demonstrate being in the top 20th percentile of your competition on carbon reduction.

The asphalt pavement industry has a proud record of sustainability using RAP, warm-mix asphalt, and other innovations that have been deployed in the market. These technologies came about through competition, not mandates. The Federal government is aware not to mandate a particular technology, but rather set up a competitive playing field that gives a distinct advantage to those contractors willing to play.

On the bright side, EPDs is just another way to demonstrate each companies’ environmental footprint of their construction material. With the passage of the multi-year Infrastructure Investment & Jobs ACT (IIJA) and IRA, times have changed and setting the clock back is not going to happen. So, get on board the EPD highway and let’s grow this market!

__________

Emerald Eco-Label, NAPA’s verified Environmental Product Declaration (EPD) tool, makes it easy to quantify the environmental impact of an asphalt mix. Created by industry professionals and stakeholders and evaluated by sustainability experts, the Emerald Eco-Label EPD tool was developed in conformance with ISO 14025 and EN 15804, which establish principles and procedures for developing a Type III environmental declaration program and describes the potential environmental impacts of a product.

ABOUT THE AUTHOR

Jay Hansen joined Surface Tech following a long and distinguished career at the National Asphalt Pavement Association and in the U.S. Congress where he worked on legislation from the Intermodal Surface Transportation Act (ISTEA) in 1991, to the Infrastructure Investment and Jobs Act (IIJA) in 2021. Jay will serve as an ongoing resource for Surface Tech customers to help them get ahead of the growth curve and be ready for shifting market conditions as they occur in 2023 and beyond.